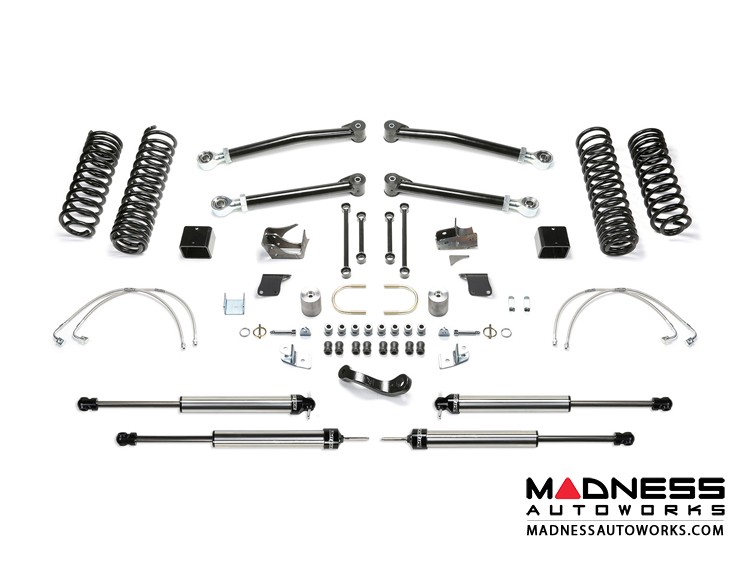

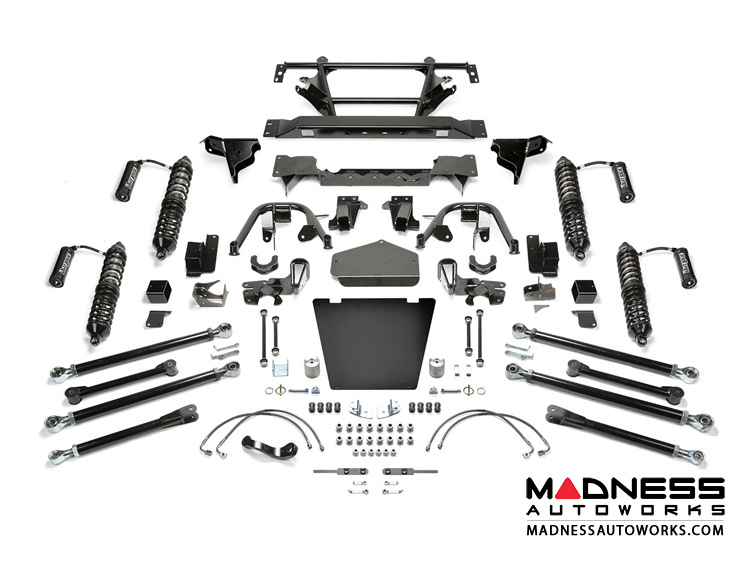

Jeep Wrangler 5" Long Travel Trail System w/ 2.25 Non Resi Dirt Logic Shocks by FABTECH - 4 Door JK (Short Arm)

Jeep Wrangler 5" Long Travel Trail System w/ 2.25 Non Resi Dirt Logic Shocks by FABTECH - 4 Door JK (Short Arm)

Drive now, Pay later!

This Short Arm Trail system replaces all four lower link arms because of their vulnerability to obstacles out on the trail. The heavy duty Link Arms maintain factory parallel joint angles in effort to reduce bushing wear. Constructed of .250” thick wall tubing and 5 Ton Joints, this system is guaranteed to hold up to the abuse. The 1/4" thick front and rear track bar brackets weld on and re-centers the axles to accommodate for the increased ride height. This system includes Fabtech’s dual rate long travel coil springs for balanced performance.

Trail Long Travel Systems Include:

- Lower Short Arm Links Front & Rear

- Long Travel Coil Springs Front & Rear

- Lower Long Travel Shock Brackets Front

- Track Bar Brackets Front & Rear

- Sway Bar Links Front & Rear

- Pitman Arm

- Brake Lines Front & Rear

- E Brake Bracket

- Bump Stop Extensions Front

- Bump Stop Brackets Rear

- Optional Upper Links available

- USE 37/12.50R17 TIRE W/ 17X9 WHEELS W/ 4.5” BS W/ CUTTING

- USE 37/12.50R18 TIRE W/ 18X9 WHEELS W/ 4.5” BS W/ CUTTING

- USE 37/12.50R20 TIRE W/ 20X9 WHEELS W/ 5” BS W/ CUTTING

- INSTALLATION REQUIRES WELDING.

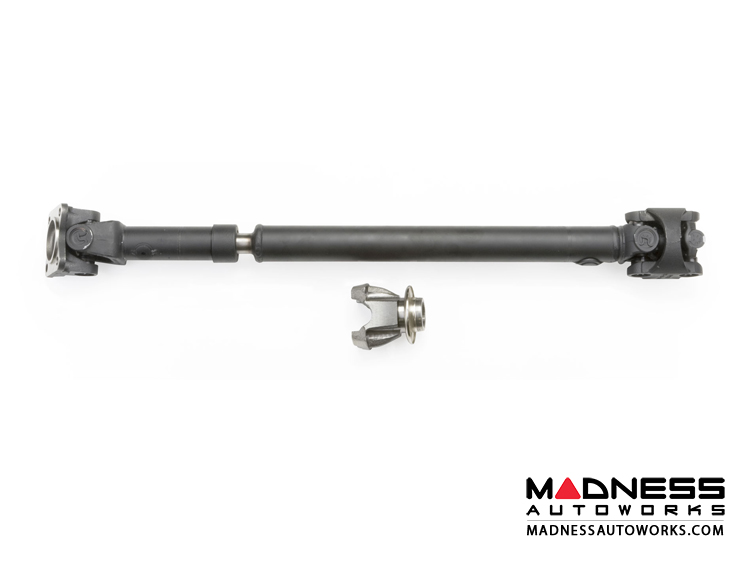

- REQUIRES DRIVESHAFTS 4 DOOR MODELS 07-11 FRONT (FTS94057) REAR (FTS94052).

- REQUIRES DRIVESHAFTS 4 DOOR MODEL 12-17 FRONT (FTS94057) REAR (FTS94059).

CA Residents: